Optical component testing is crucial for ensuring the reliability and performance of optical systems. In an era where technology is rapidly advancing, understanding the importance of this testing can make a significant difference in the quality and longevity of optical devices.

What Is Optical Component Testing?

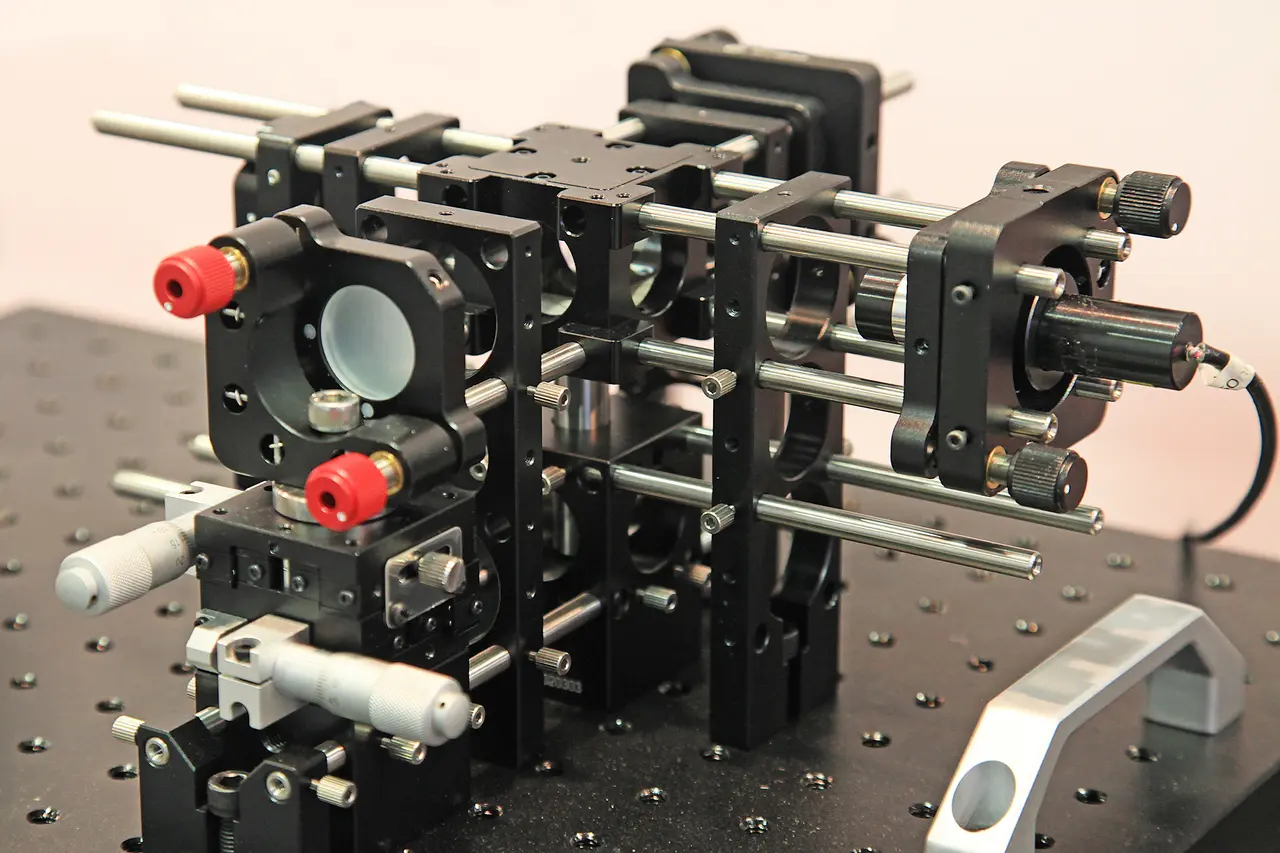

Optical component testing involves various techniques and processes to evaluate the performance, quality, and reliability of optical components such as lenses, mirrors, and fiber optics.

This testing is not a one-size-fits-all approach. Depending on the component’s type and its intended application, a variety of methods might be used. For example, specialized tests for lenses will differ significantly from those used for fiber optics source.

Understanding the basics of optical design can help appreciate the nuances of optical component testing. The design process itself lays the groundwork for testing parameters, as it involves intricate calculations and material selections that will later be scrutinized through various tests source-. Testing these designs ensures they meet the desired specifications.

The goal of optical component testing is to validate that the components will function as intended in real-world conditions. This includes assessing how they handle light transmission, reflectivity, and environmental stressors.

Why Is It Critical for Performance?

Reliable testing ensures that optical components perform optimally under different conditions, which is essential for applications like telecommunications, medical devices, and imaging systems.

In industries such as telecommunications, even minor imperfections in optical components can lead to significant data transmission errors and signal losses. Testing these components beforehand ensures that they meet the stringent requirements needed for reliable communication networks source.

Medical devices that rely on optical systems, like endoscopes and imaging equipment, demand a high degree of accuracy and reliability. Comprehensive optical component testing helps prevent potential malfunctions, ensuring patient safety and effective diagnostics.

For imaging systems, such as cameras and microscopes, the clarity and sharpness of the image depend on the flawless performance of every optical component. Rigorous testing detects and corrects issues early, leading to superior image quality.

Innovations in optical design, such as photonic integrated circuits, benefit immensely from optical component testing. These advanced components undergo specialized tests to verify their intricate functionalities and ensure they meet their performance benchmarks.

What Are the Key Testing Methods?

Common methods include interferometry, spectroscopy, and environmental testing. Each method has its own set of benefits and is used to test different aspects of the optical components.

Interferometry is a precise technique used to measure the wavefront quality and surface accuracy of optical components. It helps in detecting and quantifying minute surface deviations that could affect performance.

Spectroscopy involves studying how optical components interact with different wavelengths of light. This method is essential for characterizing components that operate across various spectral ranges, ensuring they function optimally in their intended applications.

Environmental testing simulates different conditions like extreme temperatures, humidity, and mechanical stresses to see how components withstand these challenges. This is crucial for components used in harsh environments, ensuring durability and reliability source.

Swept wavelength testing is particularly beneficial for fiber optics. This method collects comprehensive data on insertion loss, polarization dependent loss, return loss, and directivity to provide a complete picture of a component’s performance source.

How Does Testing Enhance Safety?

Proper testing helps in identifying potential issues that could lead to failures or accidents, thus ensuring the safety of both the device and the user.

In industries such as aerospace and defense, the stakes are incredibly high. Components must meet the highest standards of reliability and performance to prevent catastrophic failures. Rigorous testing ensures these components can withstand the demanding conditions they will face source.

In medical applications, optical components must be thoroughly tested to ensure they do not pose any risk to patients. Reliable and well-tested components reduce the chances of malfunctions during critical procedures, safeguarding patient health.

Testing also plays a crucial role in consumer products such as eyewear and cameras, ensuring they are safe for everyday use. By identifying and rectifying issues during the testing phase, manufacturers can prevent potential injuries or poor product experiences.

What Role Does Testing Play in Compliance?

Optical components must meet specific industry standards and regulations. Testing helps ensure compliance, preventing legal issues and ensuring market readiness.

For companies involved in sensitive industries like defense and aerospace, adherence to compliance regulations is non-negotiable. For instance, ios Optics is an ITAR registered company, which means we strictly adhere to international standards. This compliance ensures our components are safe, reliable, and ready for global use source.

Compliance with industry standards also builds trust with customers and partners. Knowing that a company’s optical components have undergone rigorous testing and meet all regulatory requirements provides a significant level of confidence and assurance.

Meeting compliance standards through thorough testing also facilitates smoother market entry, reducing the risk of recalls or legal hurdles. It ensures that products are ready for distribution and use across various regions and markets.

Key Takeaways on Optical Component Testing

In summary, optical component testing is a vital process that ensures the quality, reliability, and performance of optical systems. Whether it’s for safety reasons, to ensure high performance, or to comply with industry standards, testing plays a key role in the optical industry.